The CMS-01A High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity is the most advantageous version among the technical improvement and upgrade of products of same kind in the world. The automatic constant temperature and humidity control system was first proposed and applied in the High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity by the Company, and has obtained the national patents at No. ZL2012 20533766.2 (semiconductor refrigeration) and No. ZL2013 20497422.5 (compressor refrigeration). This technology and other technologies such as reflective grating ruler for stroke control have represented that our technology in the field of High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity is ahead of domestic and foreign products of same kind.

CMS-01A High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity

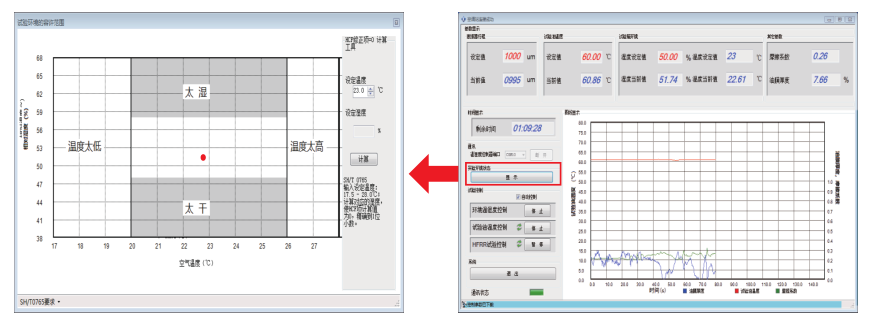

Automatic Air Condition Control System

1. Significance of environment temperature and humidity control of test oil

The assessment test of diesel fuel lubricity is a quantitative test with high precision requirement, and has the strict requirements on the temperature and humidity in the test cabinet. The standards ISO 12156-1 stipulate a dynamic allowable environment temperature and humidity range via chart. The accurate control on the temperature and humidity in the test cabinet affects the test result obviously. Meanwhile, for the calculation of mean value of corrected abrasion spot WS1.4, the different temperature and humidity changes affect the repeatability and reproducibility of test result directly due to the existence of temperature and humidity correction factor HCF.

The revised standard ISO 12156-1 has updated evaluation method of diesel fuel lubricity, and reduced the allowable temperature and humidity range of test environment obviously compared with the standard before revision. Meanwhile, the mean diameter of abrasion spot, not the mean diameter of abrasion spot corrected as per temperature and humidity, is used as the final test result. Therefore, in order to meet the revised standard, the test method has the stricter requirement on the temperature and humidity of test environment so it is necessary to use the Automatic Air Condition Control System to control the test environment.

2. Perfect basic configuration

The Automatic Air Condition Control System, as one of basic configurations of CMS-01A High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity manufactured by Beijing Gaoke, consists of CMS-01A temperature and humidity controller and constant temperature and humidity test cabinet. The basic temperature and humidity control system has the perfect environment control functions including but not limited to heating, cooling, humidifying and drying. During test, the computer can adjust the temperature and humidity control system automatically in accordance with the user’s setting to meet the routine test requirements of the user having the good laboratory environment.

In need of outstanding environment temperature and humidity control capacity, the user is recommended to select the enhanced Automatic Air Condition Control System designed by the Company for the ordinary worksite; this system uses the compressor as the independent air regulator, and has the stronger and more effective control ability on the environment in the test cabinet; Even if on the work site that cannot meet the perfect laboratory environment control requirements, this device can maintain the stable and reliable temperature and humidity in the test cabinet.

3. Proprietary innovative technology

The Automatic Air Condition Control System was first proposed and applied in the High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity by the Company, and has obtained the Chinese patents at No. ZL2012 20533766.2 (basic type: semiconductor refrigeration) and No. ZL2013 20497422.5 (enhanced type: compressor refrigeration).

4. Flexible update service

The enhanced Automatic Air Condition Control System, whose software and hardware can operate separately, can provide the perfect test environment control capacity for the High-frequency reciprocating rig (HFRR) for assessment of diesel fuel lubricity without similar function; the user can bring forward the specific configuration requirements, and the Company can upgrade this system directly based on the user’s existing equipment. This system is also applicable to other test equipment needing the similar environment control capacity.

Comparison between the Automatic Air Condition Control System matching the CMS-01 tester and the conventional temperature and humidity control mode

1. Temperature control

The test environment temperature controllers of imported and other testers have the heating function only, not the cooling function.

In summer when the air temperature increases, even if in the room with air conditioner, the heating elements in the test cabinet will increase the temperature in the cabinet continuously so the test cabinet without cooling function cannot maintain the temperature within the allowable range required by the rest method; however, the Automatic Air Condition Control System matching the CMS-01 tester has both heating and cooling functions, and can control the temperature in the test cabinet rapidly within the allowable range stipulated by the test method

2. Humidity control

The other testers use the different saturated saline solutions to control the humidity in the test cabinet, and this operation is complex and need a long preparation time; in case of damp weather, it is more difficult to use the saturated saline solution for dehumidification, and the relative humidity in the test cabinet cannot be maintained in the allowable range required by the test method in a short period so that the test is delayed and cannot be performed normally. In some regions, the control of relative humidity by the saturated saline solution is inefficient and needs a long waiting time so the work progress is affected; additionally, the long-period use of saturated saline solution may corrode the equipment to some extent, worsen the working parts of testing device, sensors and sampling circuits in the test cabinet, and shorten the service life of equipment.

The Automatic Air Condition Control System matching the CMS-01 tester controls the environment temperature and humidity automatically, is not affected by time, location and seasonal climate, and can operate stably and reliably. The control units in the test cabinet, including but not limited to heading, cooling, humidifying and drying, adjust the environment in the test cabinet by the safe physical method, and have no bad effect on any device in the cabinet. When preparing for test, this system can adjust and control the temperature and humidity in the test cabinet within the allowable range required by the test method in about 10 minutes so the test convenience and accuracy are fully guaranteed.

3. Adaptability to environmental disturbance

During the test environment control of other testers, the user cannot take measures to stabilize the test environment in case of change of external environment so it is impossible to ensure that the temperature and humidity indexes during the whole test are within the allowable range required by the test method; the calculation of corrected value of test result just uses the temperature and humidity when the test starts and ends, and does not consider the effect of temperature and humidity change on the test result during the test so even if the above two sampling values are within the allowable range, the actual test result is affected by the environment change. Obviously, the use of conventional temperature and humidity control method increases the uncertainty of test result.

The Automatic Air Condition Control System matching the CMS-01 tester ensures that the actual temperature and humidity are within the allowable range required by the test method, has the strong adaptability to the environment disturbance, guarantees the conformity of environment temperature and humidity with the method requirement during the whole test, and reduces the uncertainty of test result obviously.

Split type compressor constant temperature and humidity control system

It can be automatically controlled and adjusted according to the temperature and

humidity inside the test chamber

1. The host box and temperature and humidity controller are connected separately to avoid resonance; The temperature and humidity controller is a separate instrument unit, which is characterized by the ability to automatically adjust the temperature and humidity values according to the set values, ensuring that the temperature and humidity values throughout the entire experimental process meet the steady-state error values of their set values.

2. Stainless steel with built-in filling design has good insulation and moisturizing effects, improving control accuracy.

3. Meets the temperature and humidity requirements of the arbitration test in NB/SH/T 0765, IS0 12156.1, and ASTM D6079 test method standards.

1. The temperature and humidity control system has the function of static parameter setting and sensor reading calibration; When the temperature and humidity inside the test chamber meet the standard requirements, the experimental process can be automatically started without manual operation.

2. During the experiment, the temperature and humidity control situation can be viewed in real time, and the red dot in the above figure represents the real-time dynamic display inside the test chamber.

3. When the temperature and humidity exceed the standard setting range during the experiment, a red warning will appear in the test report results.

4. The temperature and humidity control host can set and adjust the temperature and humidity values in the software operating platform, and the changes in temperature and humidity values can be observed in real time during the test process。